Our Capabilites

Precision Injection Molding Machine

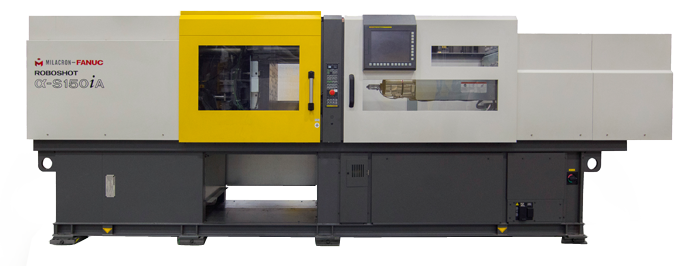

High Precision Electric Injection Molding Machine

Roboshot is the next generation of artificial intelligence (AI) in injection molding machines, with higher accuracy and reliable molding capabilities than ever before. Designed for increased rigidity, Roboshot’s proven performance makes it the perfect solution for cleanrooms and other molding environments where precise process control, high-speed injection, and consistent repeatability are required.

| Precision Tolerance | High Precision Tolerance | ||||

| Size | 1~20 (+/-mm) | 20~100 (+/-mm) | 101~160 (+/-mm) | 130 | 355×340 |

| α-S33iA | 8.0 – 27.0 | 230 | 560 | 150 | 440×420 |

| α-S55iB | 8.0 – 72.0 | 250 | 710 | 210 | 500×470 |

| α-S110iB | 11.0 – 171.0 | 350 | 970 | 220 | 660×610 |

| α-S140iB | 11.0 – 171.0 | 400 | 1,070 | 200 | 730×730 |

| α-S165iB-m | 11.0 – 171.0 | 440 | 1,115 | 275 | 800 x 750 |

| α-S165iB | 114.0 – 416.0 | 440 | 1,115 | 275 | 800 x 750 |

| α-S240iB | 55.0 – 483.0 | 550 | 1,300 | 250 | 900 x 900 |

| α-S275iA | 114.0 – 604.0 | 600 | 1,250 | 300 | 1,030 x 960 |

| α-S330iA-m | 114.0 – 604 | 600 | 1,250 | 300 | 1,130 x 1,030 |

| α-S330iA | 178.0 – 998 | 600 | 1,250 | 300 | 1,130 x 1,030 |

| α-S500iA-m | 300.0 – 998.0 | 900 | 1,900 | 350 | 1,300 x 1,300 |

All-electric Injection Molding Machine

The tonnage of the PowerPAK all-electric injection molding machine is increased compared with similar models. With 50 to 60% energy savings compared to similar machines, the Milacron PowerPAK offers eco-friendly equipment that offers speed and repeatability, cleanliness, and the highest part productivity, quality, and profitability.

| Tonnage of Machine | Injection Molding Size Range (g) | Clamp Stroke (mm) | Mix Size (mm) | Min Mold Thickness (mm) | Size of Roller (mm) | Pull Bar Clearance (mm) |

| NTM 440 | 583 – 3,685 | 675 | 1,425 | 250 | 1,175 x 1,150 | 840×840 |

| NTM 550 | 1,077 – 3,686 | 880 | 1,720 | 250 | 1,290 x 1,290 | 920 x 920 |

| NTM 750 | 1,077 – 5,528 | 1,000 | 2,000 | 400 | 1,450 x 1,525 | 1,020 x 1,020 |

| NTM 935 | 1,077 – 5,528 | 1,200 | 2,400 | 450 | 1,735 x 1,545 | 1,250 x 1,000 |

| NTM 1125 | 1,077 – 5,528 | 1,320 | 2,640 | 400 | 2,070 x 1,800 | 1,550 x 1,200 |

The World's Latest Servo Hydraulic Injection Molding Machine

Milacron’s Q Series is the world’s newest servo hydraulic injection molding machine. The Q Series is available in tonnage ranges from 55 to 610 KN (500 to 5.500 KN) for a variety of applications and configurations. Based on Milacron’s highly regarded, reliable and in-demand Magna Toggle and F-Series machine lines, the Q Series is a true pinnacle of efficiency, consistency and global engineering.

| Tonnage of Machine | Injection Molding Size Range (g) | Clamp Stroke (mm) | Mix Size (mm) | Min Mold Thickness (mm) | Size of Roller (mm) | Pull Bar Clearance (mm) |

| 50 | 64 – 171 | 280 | 630 | 150 | 500 x 485 | 325×310 |

| 80 | 99 – 336 | 310 | 710 | 150 | 610×565 | 405 x 360 |

| 110 | 165 – 374 | 380 | 900 | 150 | 690 x 645 | 480x 435 |

| 150 | 239 – 646 | 460 | 1060 | 200 | 780 x 740 | 550×510 |

| 180 | 239 – 646 | 500 | 1,100 | 200 | 810 x 770 | 575 x 525 |

| 230 | 363 – 1,025 | 550 | 1,260 | 200 | 920 x 820 | 660 x 560 |

| 280 | 523 – 1,530 | 650 | 1,400 | 250 | 990 x 940 | 710 x 660 |

| 350 | 861- 2.179 | 720 | 1,520 | 300 | 1,120 x 1,035 | 810 x 725 |

| 450 | 861- 2.179 | 850 | 1,640 | 350 | 1,245 x 1,200 | 875×830 |

| 500 | 1,318 – 2,989 | 920 | 1,820 | 400 | 1,330 x 1,300 | 1,000 x 900 |