zhu su cheng xing

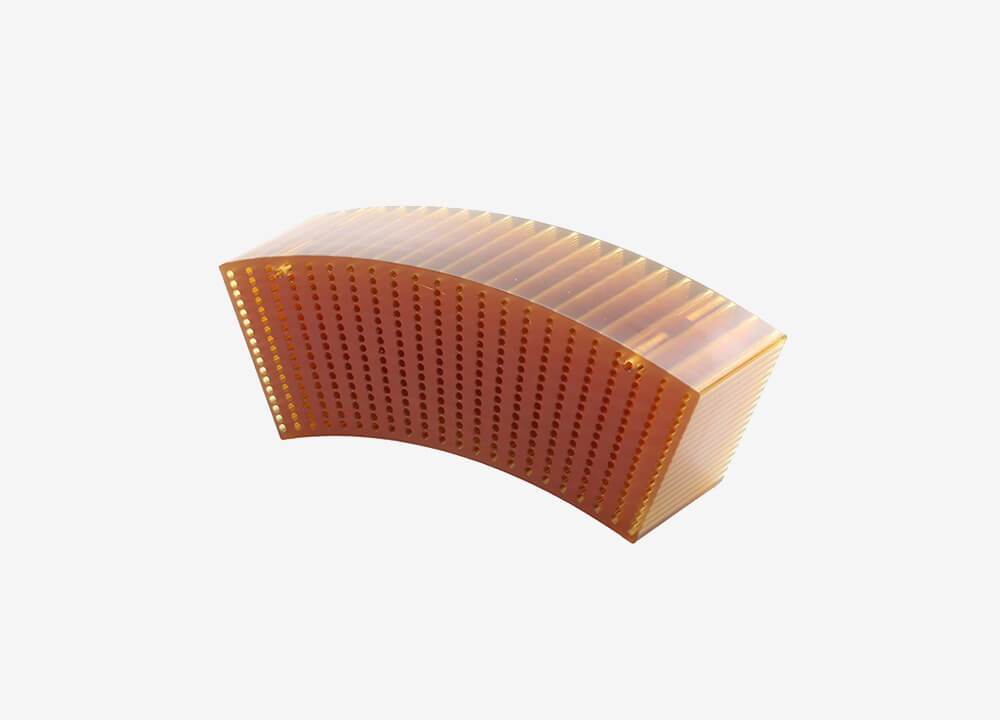

Injection Molding Services

Injection molding is a process that involves the use of "injection molding" technology. The term "injection molding" is due to the process that usually involves injecting a raw material into a mold cavity.

This approach offers many benefits in terms of production. It is the best choice for creating complex and complex parts, while also suitable for large production runs. If you want consistency, accuracy and versatility in your work, then injection molding is the best choice for you.

What is Injection Molding?

Plastic injection molding is a manufacturing process that uses thermoplastic and thermosetting polymers to produce parts. Injection molding is popular because it can create complex shapes that are difficult or impossible to make with other manufacturing methods. It also has high productivity and can manufacture parts of various sizes.

During the injection molding process, the material is fed into the hopper by a screw. This is followed by a heating process, which is then injected into the mold cavity. The heated material cools and solidifies in the shape of the mold cavity.

This approach offers many benefits in terms of production. It is the best choice for creating complex and complex parts, while also suitable for large production runs. If you want consistency, accuracy and versatility in your work, then injection molding is the best choice for you.

Advantages of Injection Molding

Plastic injection molding is a manufacturing process that uses a heated bucket to press molten plastic into a mold. The mold is then cooled and opened to release the finished product. It has several advantages over other manufacturing processes.

Produce uniform components efficiently and quickly

Can create tamper-proof characteristics

Enhanced versatility and customization

Low production cost

Rugged end product

Support complex mold design

Common Injection Molding Categories

For the cost of injection molding, we need to consider all the manufacturing processes and what those processes require. These factors include the cost of labor, the type of materials used, etc. In this section, you will learn how to calculate injection molding costs like a professional.

Plastic injection molding

Injection molding is a manufacturing process that involves melting plastic and injecting it into a mold to create a wide range of plastic parts and products.

Overmolding

Encapsulation molding is an injection molding process in which multiple strands of thermoplastic are separately injected to form a single part.

Insert Molding

Insert molding involves injecting plastic around a pre-placed insert to create a strong, durable and permanent bond between the molded plastic and the insert.

Material Selection For Injection Molding

When choosing plastic, the first thing you need to consider is the function of the part and the physical environment to which it will be exposed. There are thousands of plastic injection molding resins to choose from that have similar but not the same properties, so you have many potential solutions available.

ABS

Acrylonitrile-butadiene-styrene resin is a milky solid with a certain toughness, and the density is about 1.04~ 1.06g /cm3. It has strong corrosion resistance to acid, alkali and salt, and can also withstand a certain degree of organic solvents. ABS is a kind of resin with good mechanical toughness, wide temperature range, good dimensional stability, good chemical resistance, good electrical insulation performance and easy to manufacture.

- Application: Automotive, Electronic, office and communication equipment and other fields.

ABS / PC

PC + ABS plastics offer better strength than ABS and cost less than PC. It has high impact strength, even at low temperatures. In addition, the addition of glass fibers, mineral fillers and flame retardants to the material will also change the properties of the material.

- Application: Automotive interior parts, business machines, communication equipment, household appliances and lighting equipment

LCP

Liquid crystal polymer plastic raw materials, also known as liquid crystal polymers, the density is about 1.35-1.45g/cm3. It is a new type of polymer material, in the molten state of the general liquid crystallinity. The high orientation and rod-like properties of liquid crystal polymer molecules make their tensile strength and modulus close to that of aluminum.

- Application: Electronic, electrical, optical fiber, automotive and aerospace and other fields.

Nylon 6

Nylon 6, also known as PA6, polyamide 6, is a polymer compound. In addition to its low melting point and wide process temperature range, its chemical and physical properties are very similar to nylon 66. Nylon 6 has the lowest modulus of all nylon grades.

- Application: Auto parts, home appliances

Nylon 66

Polyadipamide, commonly known as polyamide 66, is a thermoplastic resin. Nylon 6-6 performance is better than nylon 6, the price is not as expensive as nylon 4-6. Its wear resistance is the best of all nylon, its mechanical strength, hardness, stiffness are very high. It can be used as engineering plastics and synthetic fibers.

- Applications: Mechanical and electrical parts

Nylon 11

The density of nylon 11 is 1.04g/cm3, the melting point is 185℃, the water absorption rate is 0.1-0.4℅, the tensile strength is 47-58MPa. It has the advantages of low water absorption, good oil resistance, low temperature resistance and easy processing. Because of its good cost performance, it is widely used in our lives.

- Applications: Automobile oil pipe, brake pipe, wire and cable

PBT

Polybutylene terephthalate is a milky white semi-crystalline thermoplastic polyester, one of the five major engineering plastics. It has a high heat resistance. Resistant to strong acid and alkali, resistant to organic solvents, flammable, high temperature decomposition. Widely used in automobile, mechanical equipment, precision instrument parts and other fields.

- Applications: Electrical appliances, Automobiles, Aircraft manufacturing

PC

Polycarbonate is a kind of high molecular weight polymer containing carbonate groups in the molecular chain. It is a ductile thermoplastic resin with flame retardant properties. Antioxidants. It has excellent impact strength, transparency, optical properties, mechanical properties, and can be molded to tight tolerances. PC has a wide range of applications, with a variety of compounds to choose from.

- Appliances: Glass assembly industry, automobile industry and electronics, electrical industry, industrial machinery zero

PE

The full name of polyethylene is polyethylene, which is the simplest polymer organic compound and the most widely used polymer material. PE is divided into LDPE and HDPE according to density. It has good internal lubricity and is easy to process. It should be noted that it is very soft and cannot be used at temperatures above 150 ° C.

- Applications: Film products, pipes, wire cladding

PEI

Polyether imide (PEI) is an amorphous high temperature super engineering plastic that is relatively low cost compared to other high temperature materials. It has the best high temperature resistance and dimensional stability, as well as chemical resistance, flame retardant, electrical properties, high strength, high rigidity and so on. Performance is similar to polycarbonate, but it can work at higher temperatures.

- Applications: High temperature resistant electronics, IC bases, lighting equipment

LDPE

Low density polyethylene, also known as high pressure polyethylene (LDPE), is milky, odorless, non-toxic, waxy particles with a dull surface. It has good electrical insulation, transparency, easy processing, and has certain permeability. And has strong extensibility and flexibility, so that it has excellent impact strength. This is offset by permanent deformation after impact.

- Applications: Industrial accessories, medical supplies, toys, shells, stoppers and protective covers

HDPE

High density polyethylene (HDPE) is a white powder or granular product. Non-toxic and tasteless, the use temperature can reach 100℃. It does not have the impact strength of LDPE, but is more elastic. The surface hardness, tensile strength, stiffness and other mechanical strength are higher than LDPE, close to PP, harder than PP, but the surface finish is not as good as PP.

- Applications: Industrial accessories, medical supplies, toys, shells, stoppers and protective covers

PET

PET, milky white or pale yellow, is a highly crystalline polymer with a smooth and glossy surface. Non-toxic, tasteless, hygienic and safe, can be directly used in food packaging. It has excellent physical and mechanical properties in a wide temperature range, and the long-term use temperature can reach 120°C. But it is difficult to mold very close to the tolerance.

- Applications: Capacitors, printed circuit wiring substrate, electrode groove insulation, etc

PP

Polypropylene, referred to as PP, is a colorless, odorless, non-toxic, translucent solid substance. The density is about 0.89~0.91g/cm3, and the operating temperature range is -30~140℃. It is difficult to mould to very close tolerances. Widely used in the production of clothing, medical equipment, automobiles, bicycles, parts, pipes, chemical containers and so on.

- Applications: Automotive, electrical parts, various containers, furniture

PPA

Polyphthalamide is a kind of synthetic resin with high hardness, high strength, good chemical resistance and low cost. Due to the excellent physical, thermal and electrical properties of PPA, especially the moderate cost, it has a wide range of application prospects. Although the use and introduction of PPA is relatively late, its good design data is still very useful.

- Applications: Automotive headlights, decorative fittings, military articles, sporting goods

PPS

Polyphenylene sulfide is a new type of high performance thermoplastic resin, with high mechanical strength, high temperature resistance, chemical resistance, good flame retardant, good thermal stability, excellent electrical properties and so on. Widely used in electronics, automotive, machinery, chemical and other fields.

- Applications: Machinery industry, electronic appliances, automotive industry, household appliances, chemical industry.

Acrylic

PMMA, also known as acrylic, is a tough, highly transparent material with excellent UV resistance and weather resistance. It can be colored, shaped, cut, drilled and shaped. Because of its beautiful appearance, it has a wide range of applications in the construction industry.

- Applications: Architectural applications, advertising applications, transportation applications 。

POM

POM is a crystalline plastic with a density of 1.42g/cm3. With good rigidity, it is a kind of engineering plastic with excellent comprehensive properties. POM has exhaust problems at high temperatures and is brittle at low temperatures. After the glass is filled, it can add lubrication grade and no flame retardant grade.

- Applications: Electronic and electrical, machinery, instrument, daily light industry

Polystyrene Crystal

Polystyrene crystal is a colorless transparent thermoplastic with a glass transition temperature above 100°C and is the cheapest thermoplastic. It has good optical properties. Its impact strength is very low. Widely used in all kinds of instrument shell, lamp shade, optical chemical instrument parts, etc.

- Applications: Instrument shell, lamp shade, optical chemical instrument parts, transparent film, capacitor dielectric layer, etc

PEEK

Polyether ether ketone is a special engineering plastic, with high temperature resistance, self-lubrication, easy processing, high mechanical strength and excellent properties. It can be manufactured into various mechanical parts, such as automobile gear, oil screen, shift starting disk, etc. Aircraft engine parts, automatic washing machine runner, medical equipment parts, etc.

- Applications: Aerospace, automotive manufacturing, electronics and electrical, medical and food processing.

HIPS

High impact polystyrene (HIPS) is a bright and pure amorphous plastic. It has the advantages of easy machining, good rigidity, dimensional stability and transparency, but its low impact strength limits its application. It has a lower modulus, better elongation, and is more brittle than crystalline styrene.

- Applications: Packaging, disposables, appliances and consumer appliances, toys and entertainment, construction products and decorations.

PSU

PSU is a kind of high temperature amorphous material with relatively low cost. It is transparent and has good radiation stability and heat resistance. Can be used at temperatures up to 300 degrees Fahrenheit. Widely used in medical equipment, machinery industry, electronic appliances and other fields.

- Applications: Electronic and electrical, automotive, medical equipment, aviation fields

PU

PU(polyurethane) is an extremely elastic, wear resistant, tear resistant elastic material that can be used in ether and ester based formulations. These different formulations cover a very wide range of hardness and density.

- Applications: Furniture, construction, transportation, home appliances, aviation, aerospace, automotive manufacturing fields 。

TPE

TPE(thermoplastic elastomer), also known as artificial rubber or synthetic rubber. It is a kind of elastomer with rubber elasticity at room temperature and plastic forming at high temperature. It contains thermoplastic and elastomer properties, which makes the product very easy to use in the manufacture of various products. Standard thermoplastic processing equipment and processes can be used for processing, such as extrusion, injection, blow molding, etc.

- Applications: High-grade, high transparent toys, adult products, suction cup materials, sports equipment

TPU

Thermoplastic polyurethane (TPU) is a kind of elastic material with good oil resistance, lubricity and wear resistance. It is also a mature environmental protection material. Widely used in medical health, electronic appliances, industry, sports and other fields.

- Applications: Automotive parts, tubes and hoses, films and plates, wires and cables.

Surface Finish Grade

Smooth and glossy finish

For the smoothest plastic parts, choose SPI A1, A2, or A3 grades. These dies use hardened tool steel and gritty diamond polishing for a mirror-like finish. Ideal for sunshades, plastic mirrors, and optical products.

Semi-polished surface

If your plastic parts need semi-finish treatment, it is recommended to use SPI grades B1, B2 and B3, semi-finish treatment is a good way to remove processing, processing marks. In molds with semi-shiny surfaces, sandpaper will be used for grinding.

A matte finish

For matte plastic products, opt for SPI C1, C2, or C3 grades. These molds are sand-gravel polished, ideal for industrial parts, consumer goods, and more.

Textured finish

For textured plastic parts, go for SPI D1, D2, or D3 grades. These molds are sandblasted with dry alumina or glass beads to create textured surfaces, enhancing grip, concealing imperfections, and sometimes hiding fingerprint stains.

Optional surface treatments and coatings

Finishing or coating after processing can change the appearance, surface roughness, hardness and chemical resistance of the parts produced.

polishing

pad printing

silk-screen

polishing

pad printing

silk-screen

silk-screen

Custom painting

laser marking

hot melting

Cost breakdown of injection molding

Cost of injection mold

As mentioned earlier, injection moulds come in different sizes and are sold at different prices. To buy a plastic injection mold, you might consider spending a thousand dollars or even tens of thousands of dollars, depending on the complexity of the machine. However, if you need a single cavity mold, don’t bother buying a multi-cavity mold.

Polymer resin material cost

Polymer resin quality is crucial for plastic injection molding costs. Using high-performance engineering resins for added strength and chemical resistance can increase costs compared to commodity resins like polyvinyl. For a cost-effective option, consider recycled plastic resins.

Polymer resin material cost

The choice of polymer resin significantly impacts plastic injection molding costs. Using engineering resins for added strength and chemical resistance is costlier than using commodity resins like polyvinyl. Opting for recycled plastic resins offers a more affordable option for low-cost injection molding.

labor cost

While Tebart is fully responsible for hiring the required mechanics and maintaining the machines and tool heads needed for the job, the labor costs will be partially included in the quote you receive, which is also part of the cost of custom injection molding.

Common Problem

Q: How much does the injection mold cost?

A: Prices range from a thousand dollars to tens of thousands of dollars, depending on the complexity of the mold you want.

Q: Is injection molding environmentally friendly?

A: Modern injection molding processes are more environmentally friendly. They attribute this to efficient machines, as well as durable thermosetting polymers that can withstand extreme temperatures. However, this does not mean that injection molding is absolutely safe for the environment. It also releases harmful gases that contribute to the greenhouse effect, but modern injection molding can well control this.

Q: Is there a way to reduce injection molding costs without compromising product quality?

A: Yes, there is! You can do this by reducing or removing unnecessary features like company logos, textured surfaces, and molded part numbers.